Karşıyaka Belediyesi’nin Srebrenia katliamının 26. yılında düzenlediği anma etkinliğinde konuşan Bosna Hersek Büyükelçisi Adis Alagic, Srebrenica annelerinin cesaretinin, adalet araşıyı yolunda ısrarlı mücadelesinin hepimize ilham olması gerektiğine inandığını söyledi. Alagic, “Srebrenica annelerini de unutmayalım. Onlar bize yaşanan vahşetleri ve bugün dahi yaşanan zulmü unutturmuyorlar” diye konuştu.

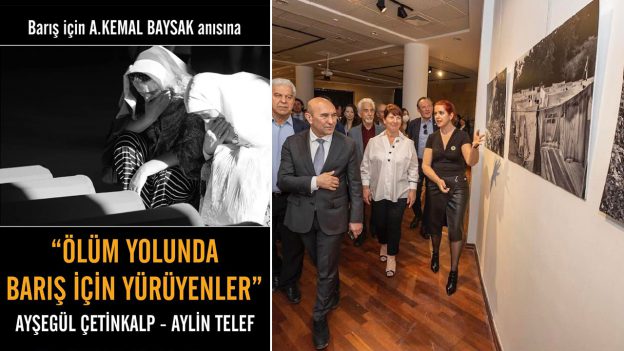

Bosna Hersek’in Srebrenica kentinde 26 yıl önce yaşanan soykırımın kurbanları çeşitli etkinliklerle anılıyor. Karşıyaka Belediyesi de Ahmet Piriştina Kültür Merkezi’nde anma etkinliği düzenledi. Anma etkinliğinde fotoğraf sanatçıları Ayşegül Çetinkalp ve Aylin Telef’in Srebrenica soykırımını konu edilen video sunumu izlendi, sanatçıların “Ölüm yolunda barış için yürüyenler” konulu sergisi gezildi. Sergide Ayşegül Çetinkalp ve Aylin Telef’in katıldıkları Marş Mira yürüyüşü ve yürüyüş sonunda Potocari Anıt Mezarlığı’daki defin töreni sırasında çektikleri fotoğraflar yer aldı.

Etkinliğe Karşıyaka Belediye Başkanı Dr. Cemil Turgay ile Karşıyaka ve İzmir Büyükşehir Belediye Meclis Üyesi ve Balkan Masası Sorumlusu Atilla Baysak ev sahipliği yaptı. Anma etkinliğine Bosna Hersek Büyükelçisi Adis Alagic, Dışişleri Bakanlığı İzmir Temsilcisi Büykelçi Naciye Gökçen Kaya, Dünya Bosna Hersek Göçmenleri Birliği Başkanı Hasan Sehovic, Türkiye Bosna Hersek Kültür Dernekleri (TBHKDF) Federasyonu Yönetim Kurulu Üyeleri Mustafa Celep ve Neccar Er, TBHKDF Danışma Kurulu üyeleri Saadet Erciyas, Hüseyin Erciyas, İzmir Bosna Sancak Kültür ve Yardımlaşma Derneği üyeleri Doğan Prepol, Nuriye Dilek Aksoy, muhtarlar, bürokratlar ve İzmir’de yaşayan Boşnak kökenli vatandaşlar katıldı.

Atilla Baysak

Video sunumun ardından söz alan Atilla Baysak, “20. Yüzyıl’ın sonunda, bu çağda, modern Avrupa’nın göbeğinde böyle bir facia meydana geldi. Binlerce insan sadece Türk ve Müslüman oldukları için katledildi. Bütün dünya gözünü kapattı, kulaklarını tıkadı. Bu çok acı bir olay” dedi. Aile olarak sık sık Bosna Hersek’i ziyaret ettilerini anlatan Belediye Meclis Üyesi ve Balkan Masası Sorumlusu Atilla Baysak, sözlerini şöyle sürdürdü:

“Köklerimiz orada, akrabalarımız var. 1878 yılında büyükbabamlar Avusturya Macaristan İmparatorluğu Bosna Hersek’e tekrar saldırdığında 1878 yılında Türkiye’ye, İzmir’e gelmişler. Şu an hala resmi, askeri haritalarda Boşnak Köyü diye geçen Küçük Çiğli’ye yerleşmişler. Bosna Hersek bizim Avrupa göbeğinde dost ve kardeş ülkemiz, bizim kendi evimiz. Bosna Hersek ile ilişkilerimizi en üst düzeyde tutmamız lazım.”

Hasan Sehovic de 1993 yılında Bosna Hersek’te savaş sürerken ailesiyle birlikte canlarını zor kurtararak Türkiye’ye sığındıklarını, o günden itibaren İzmir’de Karşıyaka’da yaşadıklarını anlattı. Bosna Hersek’te şu anda 3 milyon kişinin yaşadığını söyleyen Sehovic, “Bizim gibi Bosna Hersek’in iki milyon nüfusu yurt dışında şu anda. Nüfusun yüzde 57’si 94 ülkeye dağılmış durumda. Ne kadar büyük bir katliam ve ne kadar büyük darbe yedik, bütün dünyaya dağıldık” diye konuştu.

Bazı toplantılarda Bosna Hersek’te iç savaş olduğundan söz edildiğini söyleyen Hasan Sehovic, “Bosna Hersek’te kesinlikle iç savaş yoktu. 1991’de bağımsız olan Bosna Hersek ülkesi soykırım maksadıyla, toprakları işgal edilmek üzere saldırıya uğradı” dedi. 1992 sonlarına doğru Bosna Hersek’in yüzde 90’ının işgal altında olduğunu hatırlatan Sehovic, Sırbistan’ın Bosna Hersek’deki müslüman topluluğu yok etmek için stratejik bir planı uyguladığını söyledi.

Bazı toplantılarda Bosna Hersek’te iç savaş olduğundan söz edildiğini söyleyen Hasan Sehovic, “Bosna Hersek’te kesinlikle iç savaş yoktu. 1991’de bağımsız olan Bosna Hersek ülkesi soykırım maksadıyla, toprakları işgal edilmek üzere saldırıya uğradı” dedi. 1992 sonlarına doğru Bosna Hersek’in yüzde 90’ının işgal altında olduğunu hatırlatan Sehovic, Sırbistan’ın Bosna Hersek’deki müslüman topluluğu yok etmek için stratejik bir planı uyguladığını söyledi.

Boşnak askerlerin Alija Izetbegoviç’in komutasında kahramanca savaşarak ülkeyi adım adım işgalden kurtardığını anlatan Sehovic, şu anda Bosna Hersek’in yüzde 49’unun da Sırplar’ın kontrolü altında olduğunu dile getirdi. “Hiçbir zaman içimizde kendi çocuklarımızda intikam almak ya da kin beslemek için büyütmedik” diyen Sehovic, sözlerini “Alija Izetbegovic’in dediği gibi yaşananları hiç bir zaman unutmayacağız, unutturmayacağız. Yaşasın Bosna Hersek, yaşasın Türkiye. Ne mutlu Türküm diyene” diyerek tamamladı.

Karşıyaka Belediye Başkanı Cemil Tugay, her 11 Temmuz’da benzer anma etkinlikleri yapıldığında aynı duygunun, aynı etkiyle yaşandığını söyledi. 1995 yılında insanlığın yeryüzünün en korkunç katliamlarından birine tanık olduğunu anlatan Tugay, “Büyük bir acıyla hatırladığımız bu olay insanoğlunun geçmişten ders çıkarma, bu dünyayı tüm renkleriyle yaşayıp bölüşme konusunda ne kadar yetersiz ve unutkan olduğunu da göstermiştir” dedi. Hiçbir renk, ırk, köken, milliyetin böylesi katliamların, faciaların gerekçesi olamayacağını anlatan Cemil Tugay, “Bilinen rakamlarla en az 8 bin 372 insanın vahşice katletilmesiyle sonuçlanan bu elim olayı bugün unutmuyoruz, unutturmayacağız. Geçmişe kin besleyerek ve intikam niyetiyle değil, yaşananlardan ders çıkarmak, yeni katillerin yeni başka tuzaklar kurarak bu güzel dünyayı kan banyolarında boğmalarına fırsat ve izin vermemek için unutmadıklarını ve unutturmayacaklarını söyleyen Karşıyaka Belediye Başkanı Cemil Tugay, sözlerini şöyle sürdürdü:

Dr. Cemil Tugay

“Bosna Hersek’te çatışmaları, ölümleri engellemekle görevli ve sorumlu olanları savunmasız insanları vahşi katillerin eline terk edenleri, olanları yalnızca izlemekle yetinenleri de asla bağışlamıyoruz ve bağışlamayacağız. Hafıza olmadan gelecek öngörüsü yapılamaz. Büyük önderimiz Gazi Mustafa Kemal Atatürk ‘Yurtta barış dünyada barış’ derken yalnızca bir temenniyi değil, Srebrenica gibi faciaların yaşanmaması için her toplumda olması gereken erdemi ve kararlılığı da tanımlamıştır. Her katliam aynı zamanda toplumlara coğrafyalara insanlığa saldırıdır. dünyayı geliştirecek güzelleştirecek kuşaklar ile ürettiklerine karşı soykırımdır.”

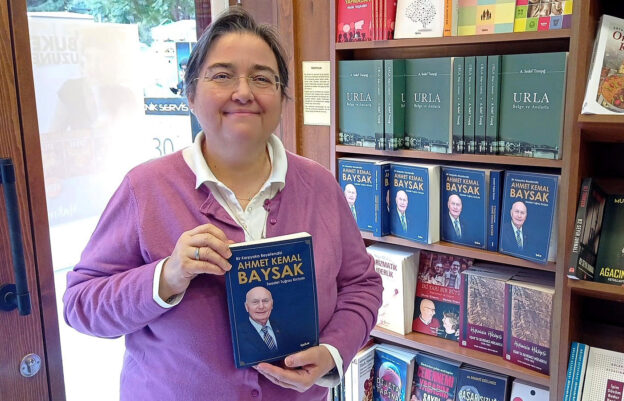

Karşıyaka’nın kalbinin Bosna Hersek’te ve dünyanın bütün Srebrenica’larında attığını söyleyen Cemil Tugay, “Bu duygu düşüncelerle yitirdiğimiz her canı saygı ve hasretle anıyor, yakınlarının ve insanlığın acısını derinden paylaşıyorum” dedi. Tugay, sözlerini, “Karşıyakamızın kahramanlarından biri olan Kemal Baysak başkanımızı, o günlerde yüzlerce Bosnalı’yı buraya getirip ayakta tutan, onlara sahip çıkan ve istedikleri zaman geri dönmeleri için yardımcı olan büyük başkanımızı yine sevgiyle, hasretle, minnetle anıyoruz. Ruhu şad olsun” diye tamamladı.

Bosna Hersek Büyükelçisi Adis Alagic, Srebrenica bölgesinde yapılan soykırım kurbanlarını hüzünle anımsarken soykırımı yaşayıp hayatta kalan ve kanlı mirasıyla her gün yeniden karşılaşanları onore etmek gerektiğini söyledi. Türk halkı, grupların ve temsilcilerinin, Boşnak halkı üzerinde yapılan soykırımın unutulmaması için çabalarını çok değerli gördüklerini belirten Alagic, “Ülkemiz Bosna Hersek’i her zaman desteklediğinizi çok iyi görüyoruz. Bunu unutmayacağız. Yapılan kötülük ve zulmün unutulmaması için samimi ve candan eforlarınızı çok iyi biliyoruz” dedi.

Adis Alagic

“Srebrenica annelerini de unutmayalım. Onlar bize yaşanan vahşetleri ve bugün dahi yaşanan zulmü unutturmuyorlar” diyen Adis Alagic, “Kendileri tüm hayatta kalan Srebrenica halkı dahil çok çektiler. En yakınlarını kaybettiler, zulüm gördüler. Hayat ve geçim mücadelesini vermeye devam ediyorlar. Buna rağmen daha güzel ve adil bir dünyaya inanmaya devam ediyorlar. Ve o yönde mesajlarını vermek için güç buluyorlar. Onların tek istedikleri adaletin yerini bulmasıdır. Kurbanlar adalete tabidir, suçlular ise cezaya” diye konuştu. Srebrenica annelerinin cesaretinin, adalet araşıyı yolunda ısrarlı mücadelesinin hepimize ilham olması gerektiğine inandığını anlatan Alagic, sözlerini şöyle sürdürdü:

“Bosna Hersek’te olan bu acılı olayların tüm dünyaya hatırlatması ve hatırlanması lazım. Bir ders çıkarması lazım. Soykırım hiçbir kimseye ve hiçbir yerde tekrarlanmaması lazım. Zulüm yenilmezse adalet galip gelmez. 8372 sayısını unutmayalım. Beş gün içinde katledilen Boşnak genç ve erkek sayısıdır bu. Tabii burada son olarak toplanmakla adalete ülkemize ve halkımıza çok önemli bir destek verdiğiniz için hepinize çok teşekkür ediyorum. Son bir sözle bitirmek istiyorum konuşmamı. Zulümden uzak olan, zulmü yaşayan yaşamış olan gibi tepki verene kadar adalet yerini bulmaz. Burada ve Türkiye’de bulunan insanlar tüm dünyada nasıl yapılması gerektiğine örnektir. Biz de bosna Hersekliler olarak sizin hak ve adalet için ne kadar mücadele vermeye eğilimli olduğunuzu görünce biz de sizi örnek alıyoruz. Hepiniz sağ olun.”

Naciye Gökçen Kaya

Dışişleri Bakanlığı İzmir Temsilcisi Büyükelçi Naciye Gökçen Kaya da Srebrenica’da yaşananların Avrupa’nın bu soykırım dünya tarihinin insanlık tarihinin bir kara lekesi olarak hafızalara kazındığını söyledi. “Demokrasi, insanlık, insan hakları konusunda bize ders vermeye çalışan Avrupa’nın gerçekleştirdiği bu soykırımı her zaman hatırlamamız, hatırlatmamız ve gerekmektedir” diyen Gökçen Kaya, “Boşnak lideri Izetbegovic’in dediği gibi, 8372 Boşnak kardeşimizin katledilişini Avrupaya Batıya her zaman hatırlatmamız bunu her zaman canlı tutmamız gerekmektir” diye konuştu. Türkiye Dışişleri Bakanlığı olarak her zaman kardeş Bosna Hersek’in yanında olduklarını vurgulayan Büyükelçi Naciye Gökçen Kaya sözlerini şöyle sürdürdü:

“Aziz şehitlerimizi kendi şehitlerimiz olarak görmekteyiz. Avrupa bu soykırımdan gerektiği kadar ders almamıştır. Avrupa müslümanları hala daha ayrımcılığa tabi tutulmaktadır. Birleşmiş Milletler gibi İkinci Dünya Savaşı’ndan sonra barışı korumak üzere kurulmuş bir örgütün eliyle veya onların göz yummasıyla gerçekleştirilmiş bir vahşeti, vahşi Srebrenica katliamını hiç bir zaman unutmayacağız, her zaman hatırlatacağız. Bu vesileyle Srebrenica katliamında hayatlarını kaybeden Boşnak kardeşlerimizin kederli ailelerine taziyelerimizi sunuyoruz, hatıraları önünde saygıyla eğiliyoruz.”